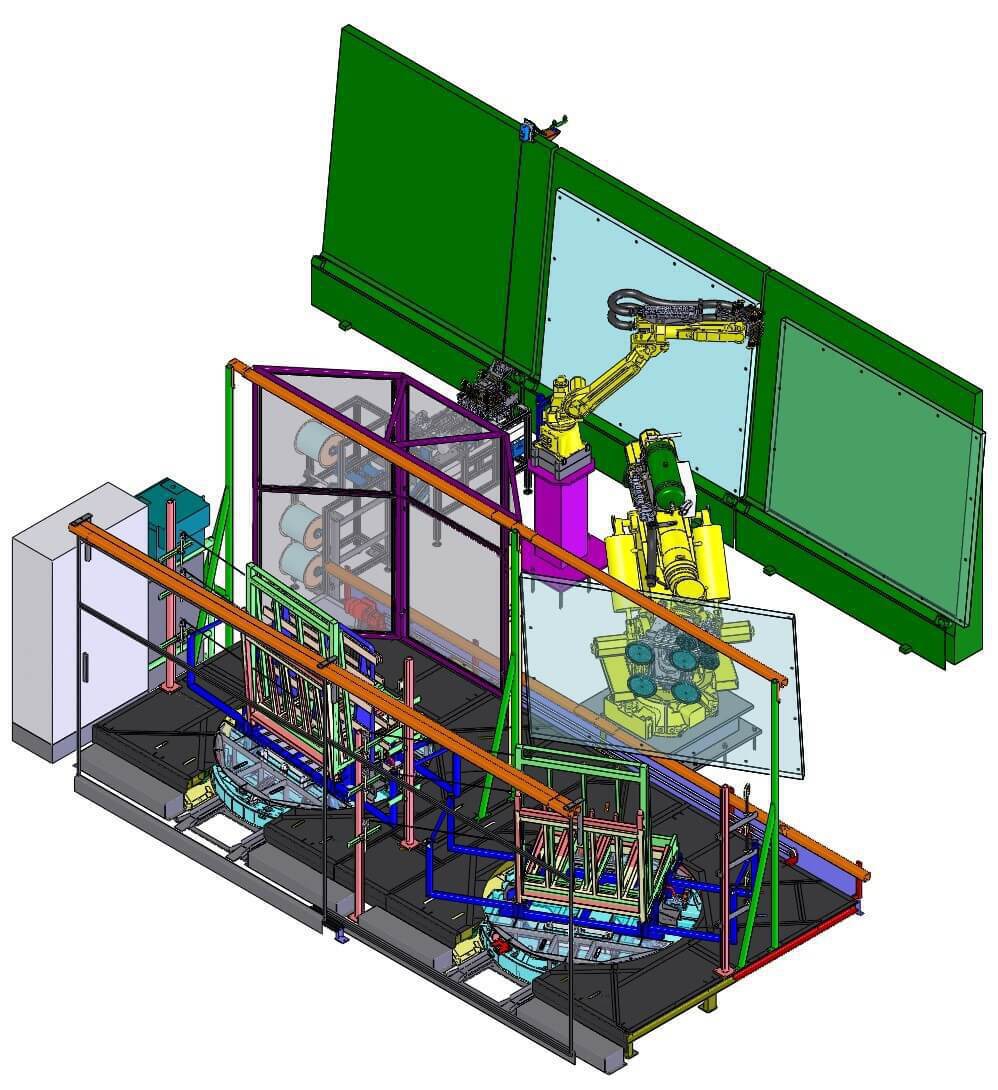

Robotic end of glass unit line

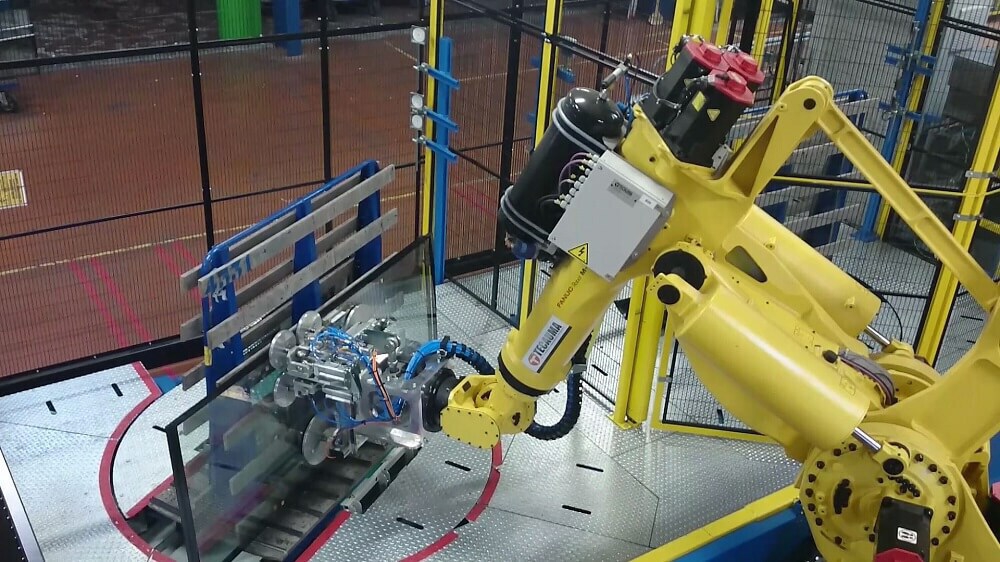

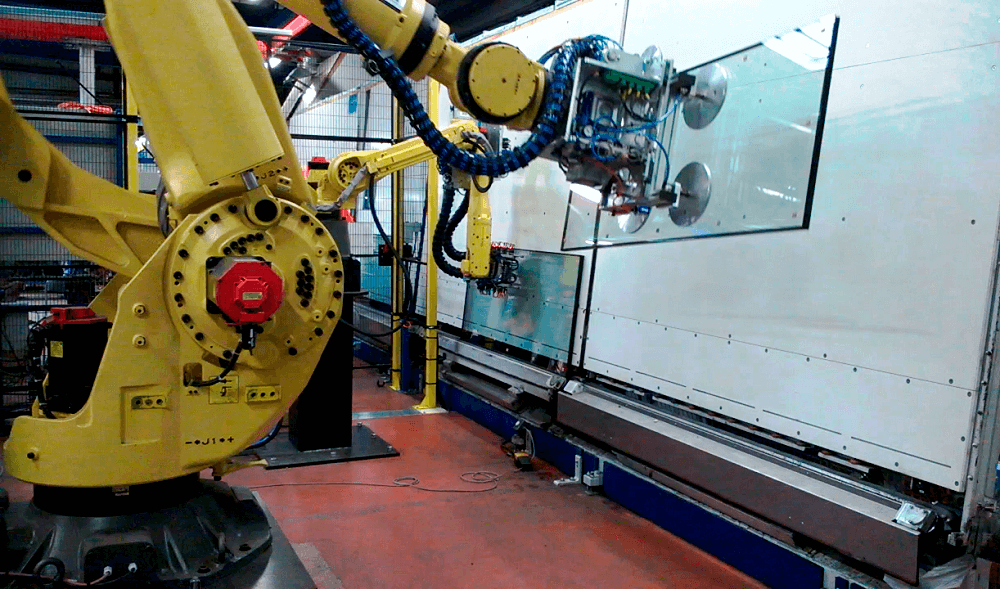

At the end of the manufacturing line of insulating glass units (IGU), TECAUMA’s the robotic cell does the palletizing of finished glasses on trolleys or racks. First, a 6 axis poly-articulated robot, put cork pads on each glass: "smart" cork pad setting, according to the size of the following glass unit on the line. At the end of the line, the glazing is handled by a second robot, equipped with a vacuum gripper. Automatically, the robot turns on itself and unload the glazing on its conditioning apparatus, in a preprogrammed position. The operations are repeated successively until complete palletization of the apparatus. The robot switches automatically to a second apparatus, thus ensuring flow continuity. A security doors system allows the change of apparatus without interruption of the production.

Technical

Features

- 6 axis robots, associated to its automatic cork pads distributor

- Size of the pads :

- Width: 18 mm.

- Length: 18 mm.

- Thickness: 3 mm

- 6 axis palletizing robot, equipped with a vacuum gripper

- Ergonomic and intuitive supervision software developed by TECAUMA

- Production rate: 25 s / glazing

- Operation carried out in tracking without stopping the glazing

- Dimensions limits of glazing:

- Height: from 190 to 2 000 mm

- Width: from 350 to 2 500 mm

- Thickness: from 14 mm to 60 mm.

- Maxi weight of glazing: 250 kg

_partage_1560256858_